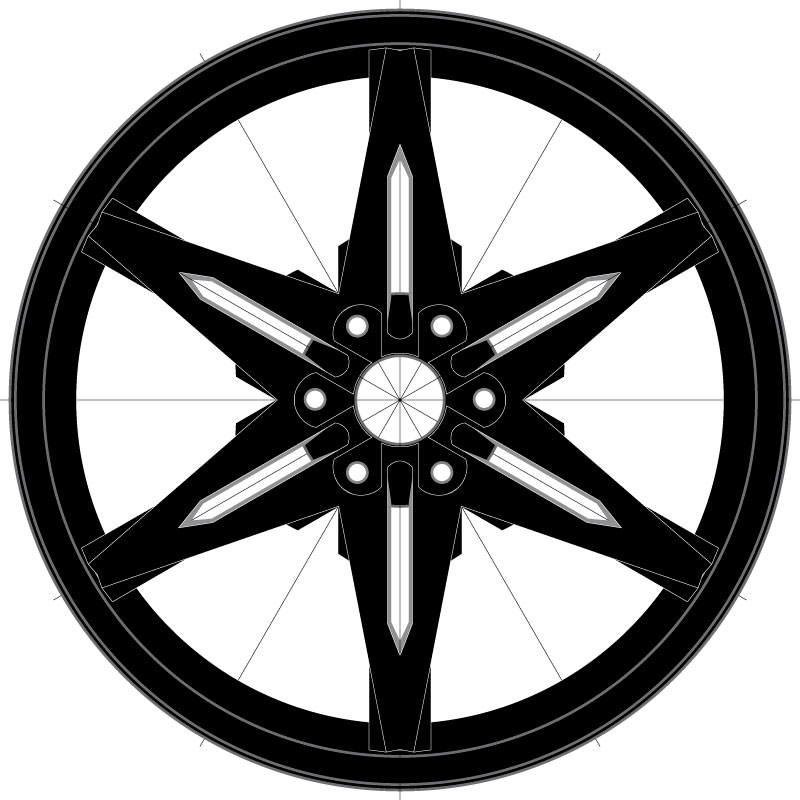

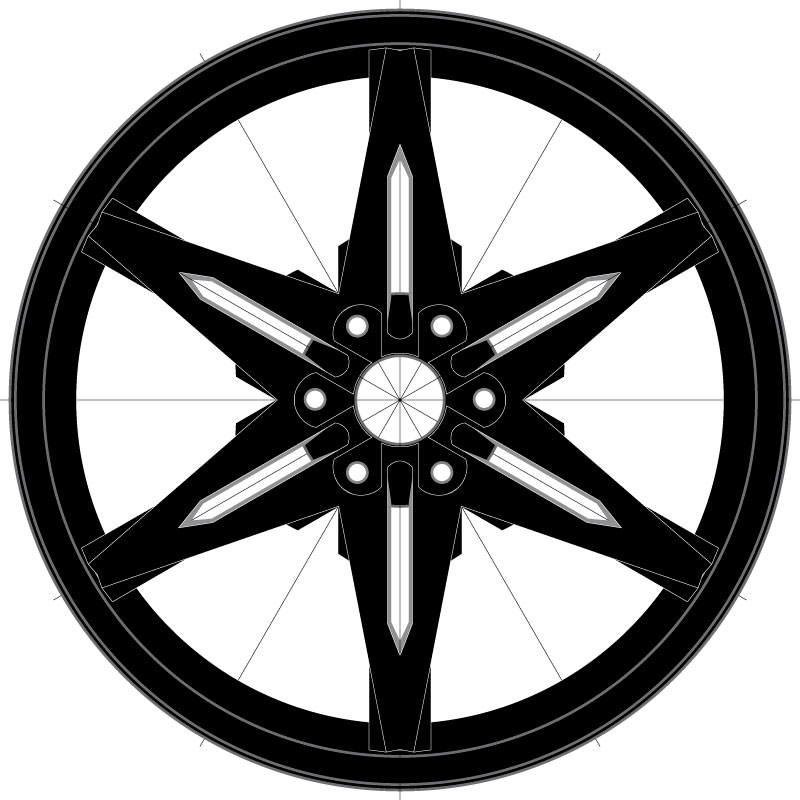

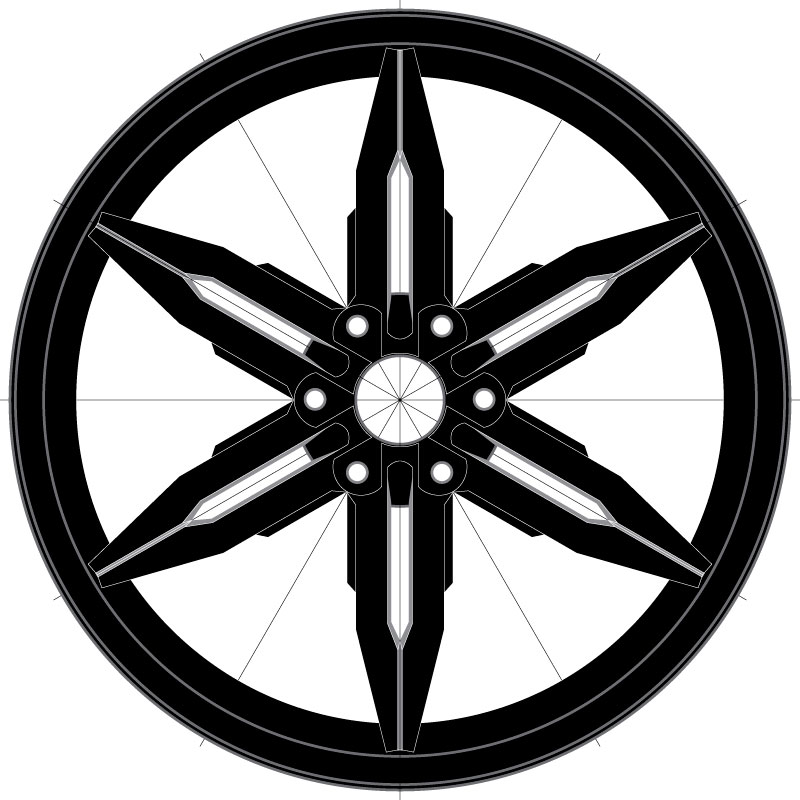

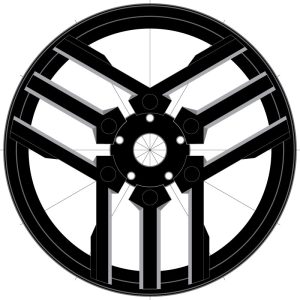

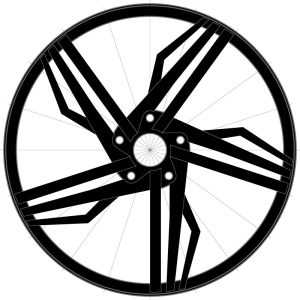

6 Lug – 20″ Wheel

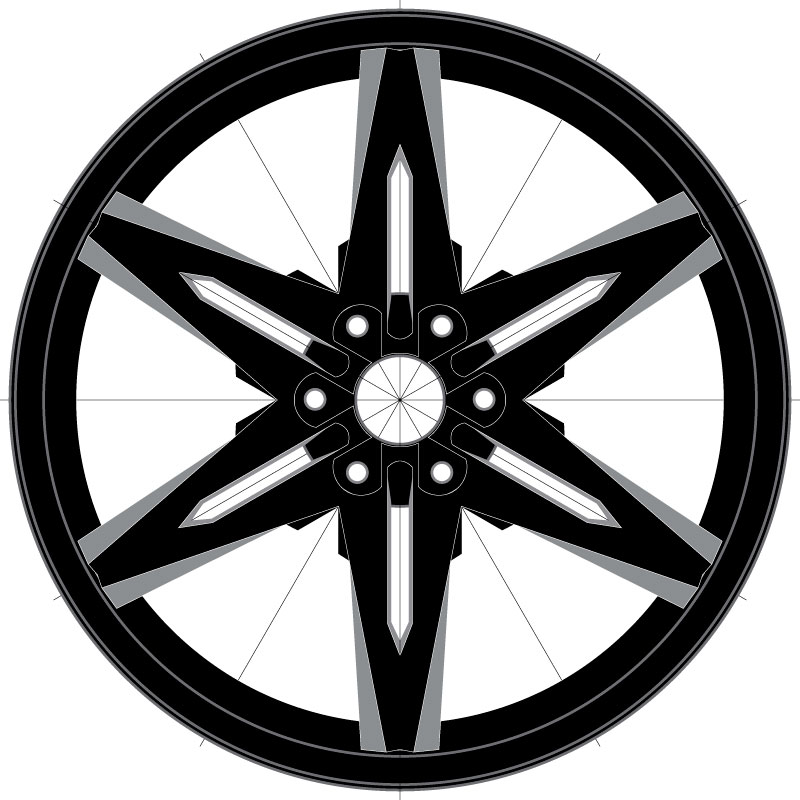

6 Lug – 20″ Wheel

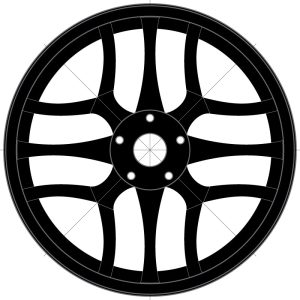

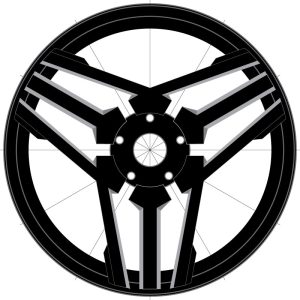

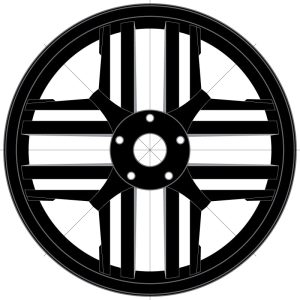

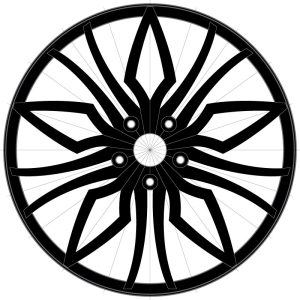

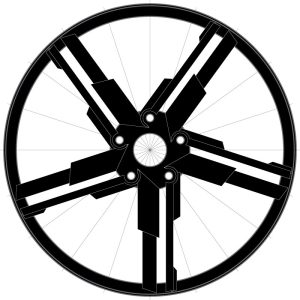

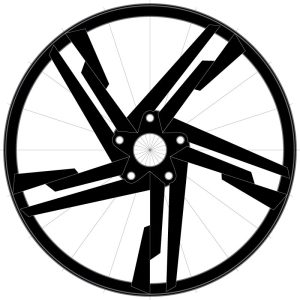

The light gray guidelines behind the wheels form wedges. By drawing in one specific wedge, it is mirrored and cast into a circular array.

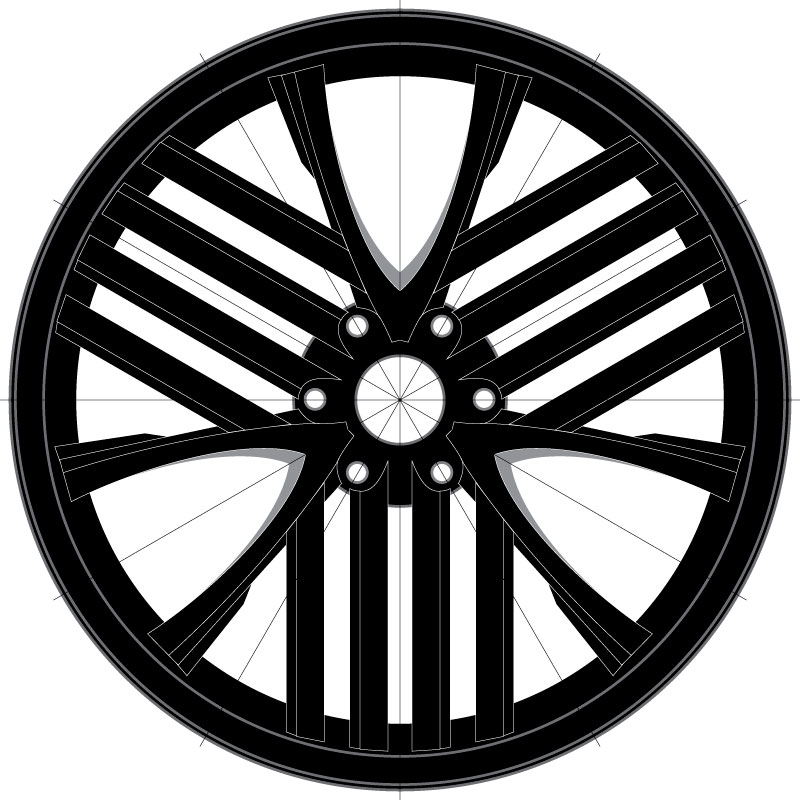

5 Lug – 20″ Wheel

The Illustrator files have a few different layers that react differently. Sometime don’t mirror. Others may only array every other spoke.

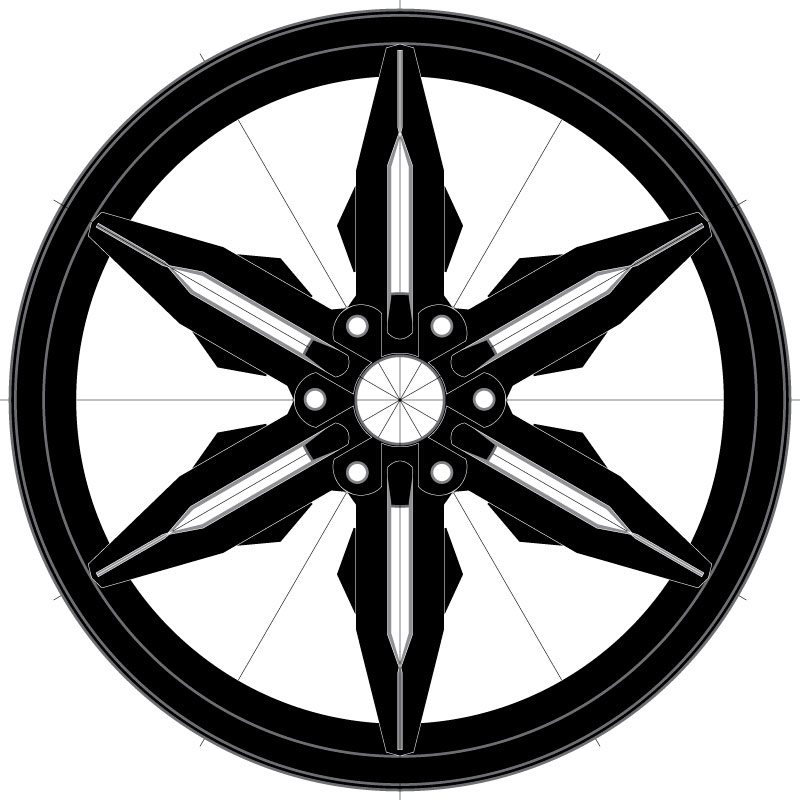

5 Lug – Thin barrel face

This set of Illustrator files is noting more than a way to conceptualize and draw wheels in around a minute.

Coming off of a career in architecture and engineering, I found myself picking up several clients in the automotive aftermarket industry. Many of them were selling custom wheels.

I was mainly doing graphics and web design for these clients, but I soon saw a way to help a few of them with product design. When coming up with a new design, they typically did old-school hand sketches. While I love the discipline, I hated the inefficiency and lack of flexibility of that method.

I had years of experience in 3d design. I already knew a few good tricks for getting from concept to completion. It was a matter of finding a “low-tech” method for users that worked easier than a pencil and paper.

I set up Adobe Illustrator files to mirror wheel spokes on an axis and then cast them into an array. What this means is that when you draw something, it automatically draws all of the other similar elements. This method of early design is perfect for things like wheels.

While it’s in 2D and doesn’t show wheel depth, this method can quickly set up a front facing concept. The rim’s hub and barrel are predefined and set to scale. You select the wheel style you want and start drawing spokes. The area you draw in even trims the outside edge of the spoke automatically. It is very simple and works incredibly well with a Wacom tablet or Cintiq.

Once a concept is tweaked and refined, it can then be exported and brought into an application like Autodesk Inventor. There a similar, but much more involved process can be used to create 3d spokes with smart constraints.

When a smart 3d model is set up, wheel variations can be easily created. By changing the dimensions of smart constraints, the model adjusts automatically providing multiple wheel diameter and width options.

These smart models can also be stress tested within a virtual environment. The tests are used to minimize the use of materials based on wheel creation method. This is done to created the lightest and strongest option for that wheel. Lighter wheels are more fuel efficient.